In the field of global residential, commercial, institutional and industrial building, insulated concrete forms (ICFs) have come up with a revolution. An insulated concrete form is a building system made from concrete, now in the limelight due to its cost effectiveness, comfort, durability, energy efficiency and safety ratings as compared to the other traditional methods of construction.

When someone talks about the home construction, a homeowner can save energy by hiring a contractor who is efficient and constructs the home quickly with Excel. A homeowner should explore the way insulated Building Concrete Forms are used to construct a house because they offer efficiency during and after construction. These forms are shipped to a construction site ready to be put into place; therefore there is less waste means that less energy is being used to haul the waste away. It is reinforced concrete act as a barrier to the outside air temperature and keeps your cost down. It can be easily installed. The finished walls with this technology will have attachment extension for exterior and interior finishes.

After the introduction of polystyrene, this ICF technology was invented. Generally, the polystyrene panels are adjustable with the plastic ties mounted in the center and implanted half inch inside the foam, which gives better stability during the movement of the wall and the addition of concrete. During the Building Concrete Forms construction, polystyrene foam locks the moisture at the time of concrete pour into the insulated panels and the final products will have the superior strength. But to install the ICF walls easily, an expert and qualified construction team is needed. So you should hire the potential contractor to do your work perfectly and the amount of labor you will need.

Now-a-days, insulated concrete forms are very popular with every home or commercial construction projects. This ICF technology is now setting a standard in building construction filed due to its greater durability and energy efficiency.

Structural Insulating Shuttering Panels, or SIPs, are multi-functional Orient Strand Boards that are made from two layers of wafer chipped wood, or particle board. The centers of these boards are tightly webbed to provide the insulation needed and can be used in walls, flooring and ceilings. In comparison to traditional insulation, SIPs are about 40% more efficient in controlling heating and cooling.

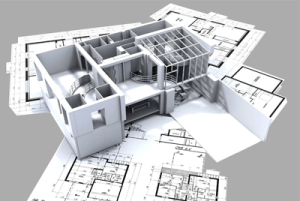

BOFU plastic formwork system