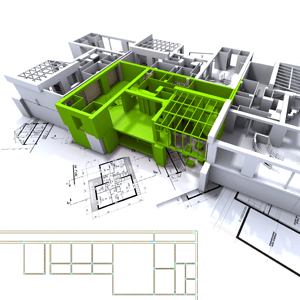

Insulated Concrete Forms:

Insulating concrete forms (ICFs) result in cast set up concrete walls that are inserted between two layers of insulation material. These frameworks are solid and energy efficient. Regular applications for this strategy for development are low-rise buildings, with property utilizes extending from residential to commercial to industrial. Conventional completions are connected to the interior and exterior confronts, so the Building Concrete Forms appear to be like regular development, despite the fact that the walls are typically thicker. The foam and concrete together give protection or insulation, expanded assurance from fire and storms, a backing for interior walls and exterior siding or brick, and energy efficiency.

The qualities that makes Insulated Concrete Forms More Popular:

Homes made with Insulated Building Concrete Forms are becoming more popular for various reasons, as given below-

Savings:

As these insulated concrete form systems save the energy of 25-80%, they are certainly worth giving a closer look. A building with ICFs may little expensive, but it saves your energy bills for as long as you live in your home. Since insulation will not be essential in addition to the ICF on exterior walls, your insulation budget can be cropped significantly.

Security:

The building with ICFs is stronger and safer than the other method. The lower infiltration of outdoor air keeps allergens outside. ICFs provide increased safety during fire and storms and other disasters. They are not even affected by moisture and less inviting to insect pests.

Soundproofing:

When we are in the home, normally expect no noise pollution. The foam and cement in ICF built buildings deliver both thermal and acoustic insulation. This can cut down on noise even between levels of the home. ICF homes may be considered to be sustainable as well. ICF homes reflect their eco-friendly nature of the increased use and cost of fossil fuels.

Insulating Shuttering Panels:

Structural Insulating Shuttering Panels, or SIPs, are multi-practical Orient Strand Boards that are produced using two layers of wafer chipped wood, or particleboard. The centers of these sheets are firmly webbed to provide the insulation required and can be used as a part of walls, flooring and ceilings.

BOFU plastic formwork system